|

Utility Mfg Falcon-Flex |

Manufactured or assembled in USA from (Circa) 1939 to (After) 1939.

Index of rarity in France: Rare (among non-specialized garage sales)

Inventory number: 9418

See the complete technical specifications

Chronology of cameras Utility Mfg

A Candid Type is defined by its use. Breaking with most previous models, these are cameras allowing spontaneous shooting. We can say that it can be applied to a multitude of cameras. Of course, we can draw some characteristics or constraints from it such as the small size for discretion, the use in natural light for spontaneity, the flash capturing the attention of the subject photographed beyond the first trigger. You also have to know how to accept some faults such as the lack of sharpness, the grain, the use of black and white. If these defects quickly disappeared thanks to an improvement in the quality of cameras and films, in the 1930s, it is still a reality.

Admittedly, a Leica can be assimilated to a Candid Type, but it is in the simplest that Galter is interested, pushing the notion of low end to its maximum. The term minimum is certainly more appropriate in the present case.

The cameras manufactured by Galter use the 127 film and give most of the time 3 x 4 cm negatives. They are sometimes made of bakelite, often of another plastic material with poor heat resistance. Moreover, we find many of his cameras with deformations without knowing if they presented them from the manufacture or if exposure to the sun is responsible.

The cameras manufactured by Galter use the 127 film and give most of the time 3 x 4 cm negatives. They are sometimes made of bakelite, often of another plastic material with poor heat resistance. Moreover, we find many of his cameras with deformations without knowing if they presented them from the manufacture or if exposure to the sun is responsible.

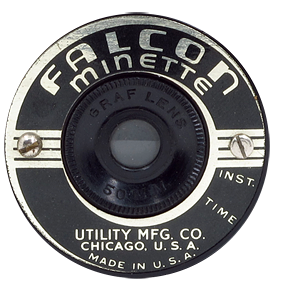

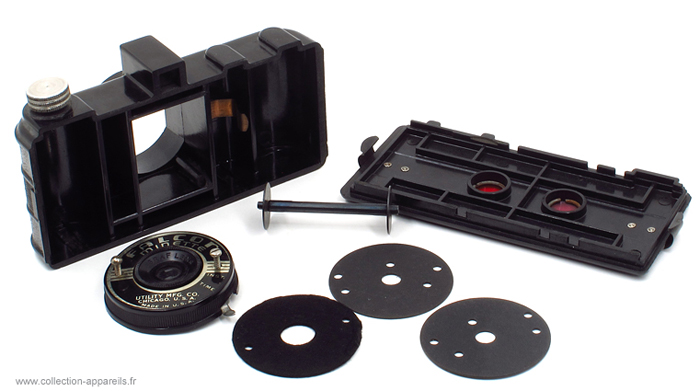

The front face is covered with a round plate, held by two screws. If they are removed, the whole lens and shutter assembly comes apart. Inside, depending on the type of mould used, there may or may not be a housing for a replacement film.

Around the front lens are the name of the lens, Graf, and the 50mm focal length. The plate is generally decorated with two metallic circles: one closest to the lens, the other at the edge of the plate. The name of the pseudo-brand is inscribed under the lens, horizontally, followed by the indication of the city of manufacture, then a “Made in U.S.A.” on the curve.

The typography is often of the same inspiration.

The shutter is without cocking. Speeds are indicated by INST. and TIME.

To manufacture a Galter camera, you have to mould the back, the front part and the shutter cover separately. In the rear part, the two inactinic windows are inserted and the two closing claws are riveted. On the largest piece fits the film advance wheel. Inside, a metal lamella holding the film in place is riveted. The element constituting the lens is inserted in the Bakelite part of the shutter. The latter is slid into the front part. Its rear face is roughly cut from thin sheet metal and bent as required. It is hidden by a felt washer, then strong cardboard wedges are installed between this block and the front part of the camera to correct the focal length. The front plate is installed, and two screws hold it all together. All you have to do is insert a spool axis, and too bad if the assembly was approximate. The assembly is very fast and does not require any technical qualification.

The cameras, despite a multitude of (fake) brand names are grouped into a few types, which results from a limited number of moulds. Some atypical cameras result from the integration of other manufacturers. Variations, based on these moulds, can have a different closure system or screws holding the coil above the protrusions.

The decorations on the front of the body may vary: horizontal lines in variable number,

Long-shaped mould, with two protrusions on the cover and thickened ends, made of Bakelite Long-shaped mould, with two protrusions on the cover and thickened ends, made of Bakelite |

Long-shaped mould, but without a second protrusion. In plastic material. |

Plump shape Plump shape |

Short form |

With pins for flash With pins for flash |

Short shape with protrusion Short shape with protrusion |

Angular mould Angular mould |

Asymmetrical shape |

shape... artistic shape... artistic |

|

Horizontal shape. Made of bakelite Horizontal shape. Made of bakelite |

Long shape, with folding viewfinder |

Vertical design imitating a TLR. Made of Bakelite or metal Vertical design imitating a TLR. Made of Bakelite or metal |

Vertical design imitating a TLR. Made of Bakelite Vertical design imitating a TLR. Made of Bakelite |

This Falcon-Flex is indeed part of the Candid Type camera, even though it is made of injected aluminum. The case is similar to the Monroe Sales Color-flex. Here, the presentation is more understated, with exposed metal parts and flat surfaces covered in black leatherette.

Its lens is the Graf 50mm typically found on cameras of this type. The aperture is indicated (Achromat 17.7/50mm) because, quite unusually, there are 3 apertures: f/7.7, f/11, and f/16.

Once again, because we are in the realm of Galter cameras, the deck is reshuffled. The brand on the front face is Utility Mfg., but the one mentioned in the manual is The Spencer Company.

Interesting links or bibliography :

Add a link or element of bibliography, a picture taken with this camera, a picture of box or an ads about this camera

Your photos taken with the same camera:

Cameras from Ebay France (Utility Mfg) (Uploaded each 3 hours)